Nan-O-Sil Technical Papers

A Study on the Effect of Nan-O-Sil ASD on Cooling Time Reduction

Jonathan Meckley, Pennsylvania State University at Erie, The Behrend College, Erie, PA

Dr. Pravin Shah, Rheoplast, Reading, PA

Richard Oder, Energy Strategy Associates, Old Chatham, NY

Abstract

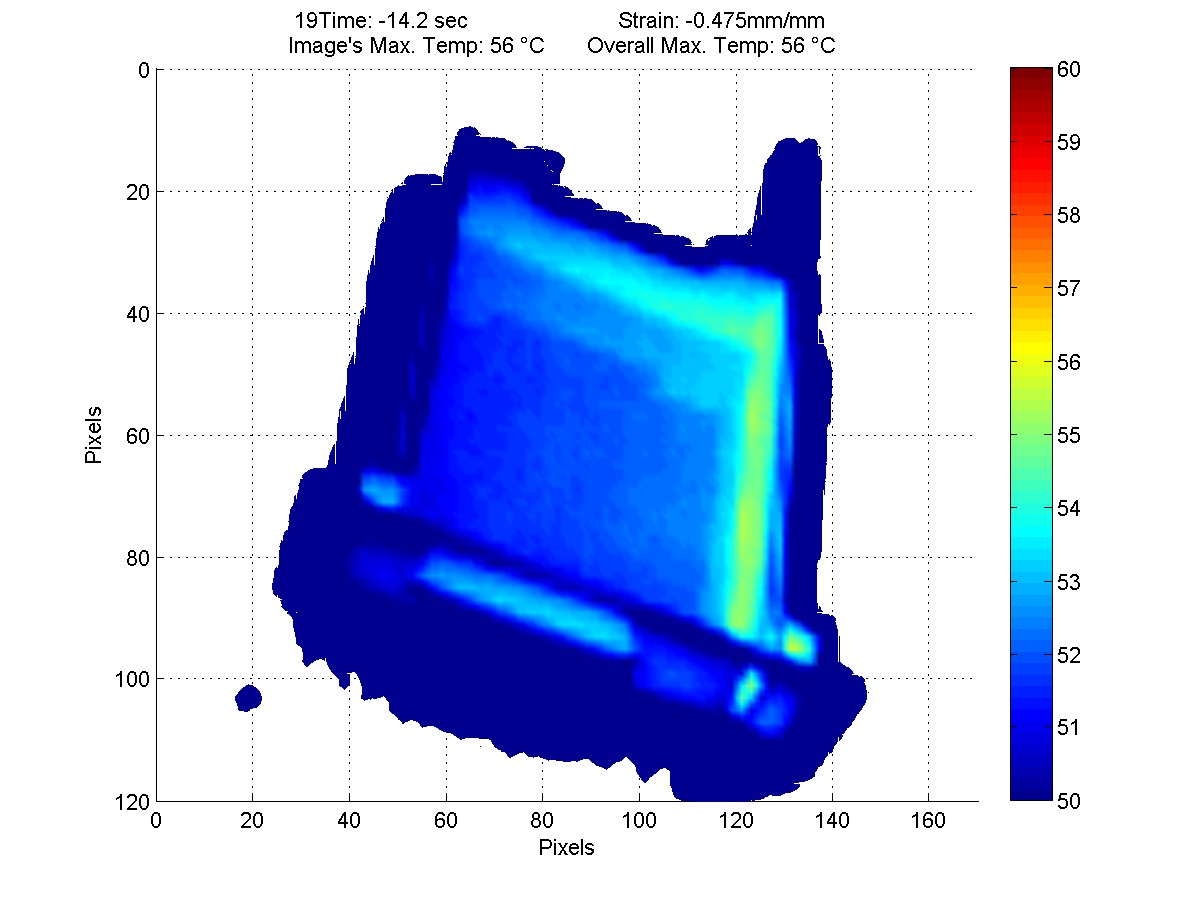

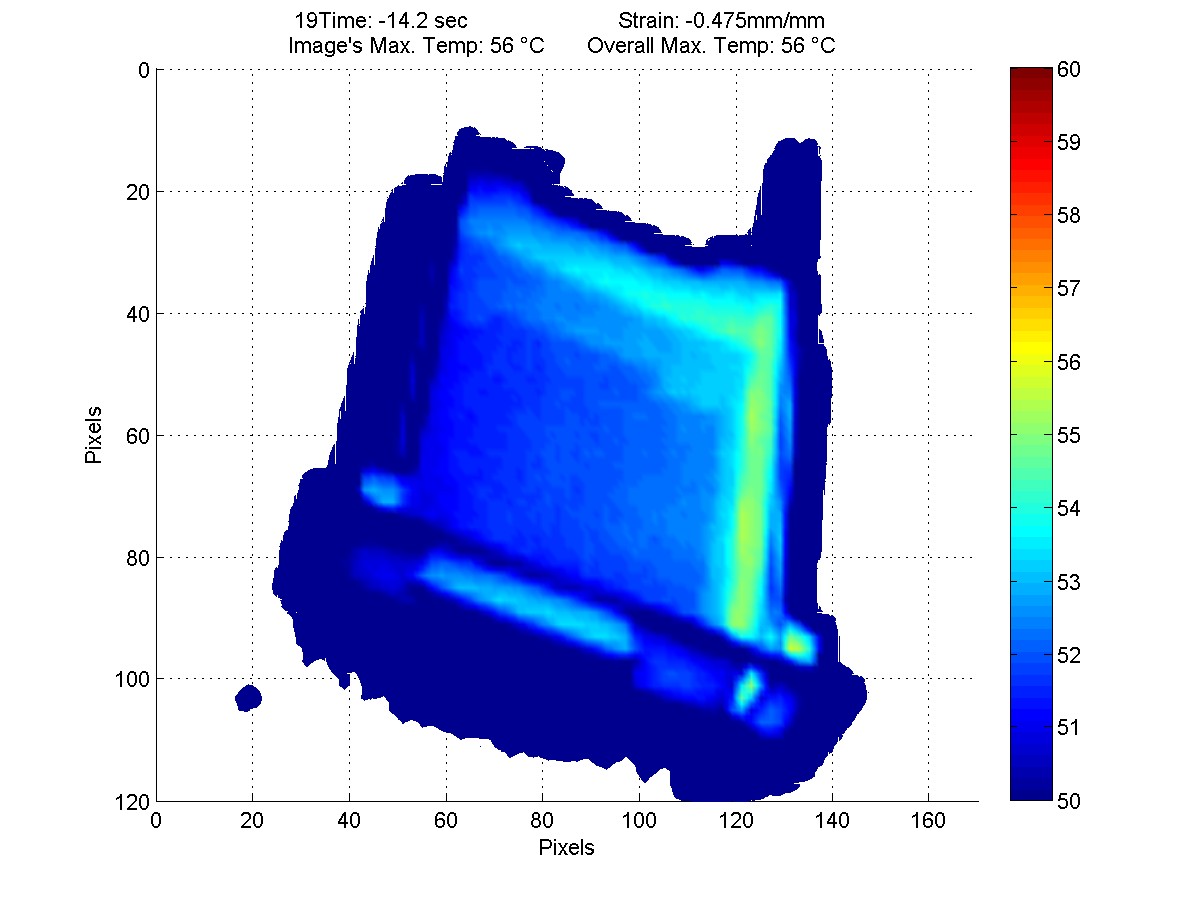

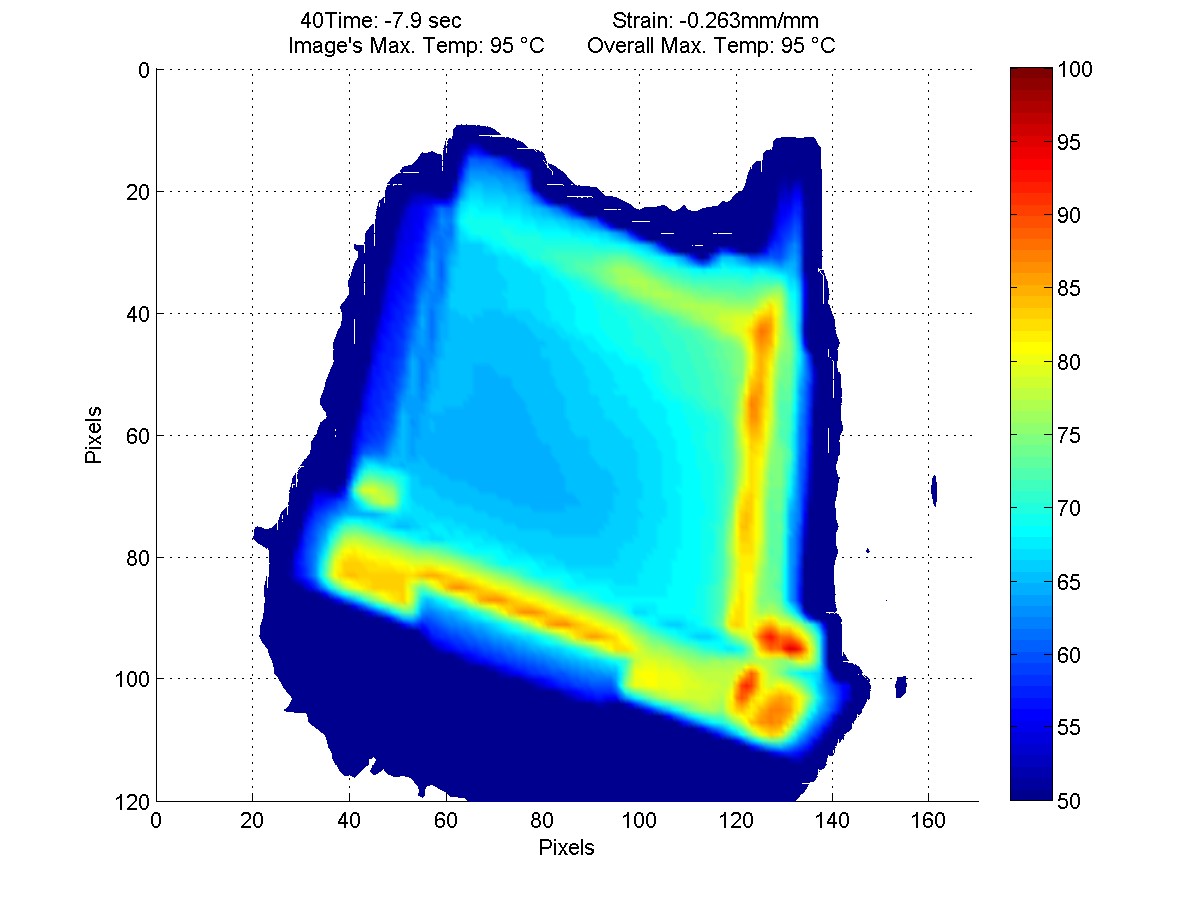

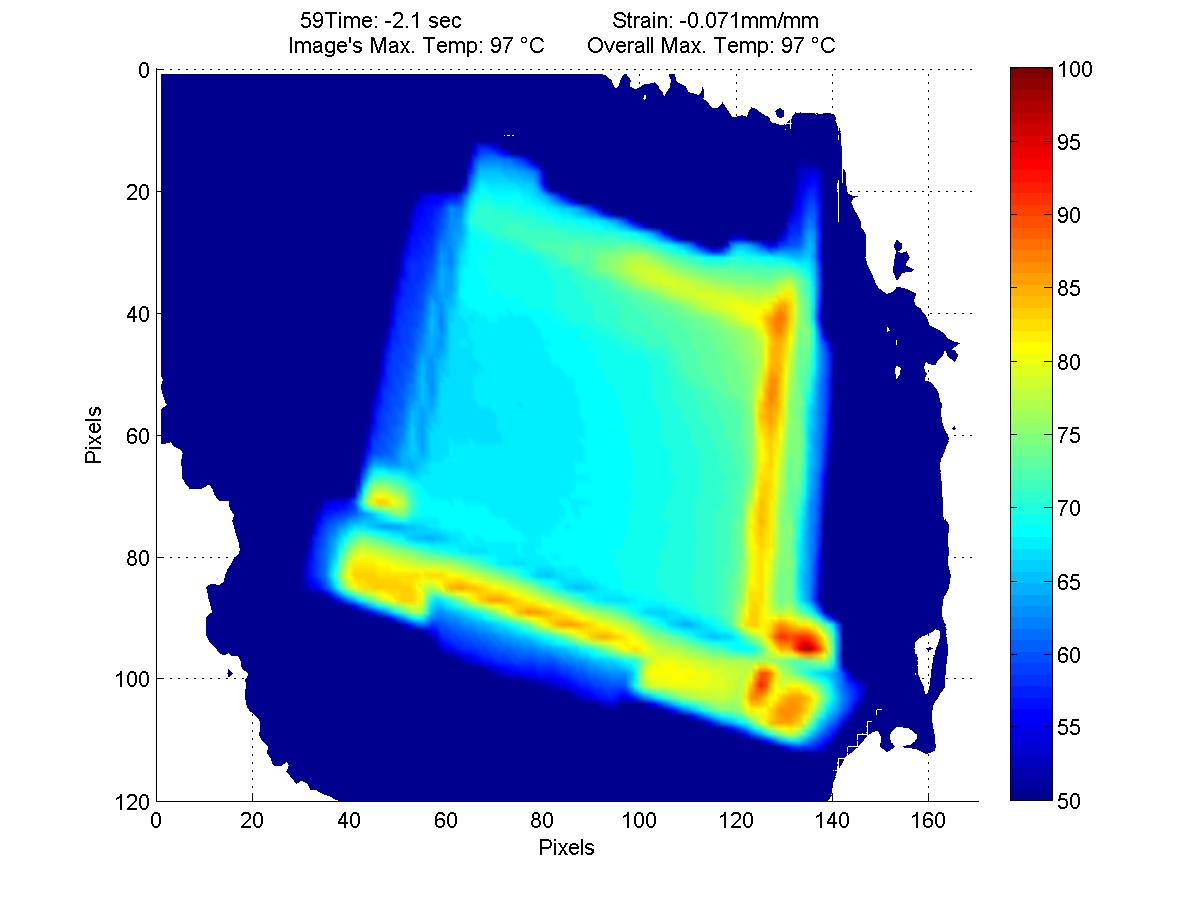

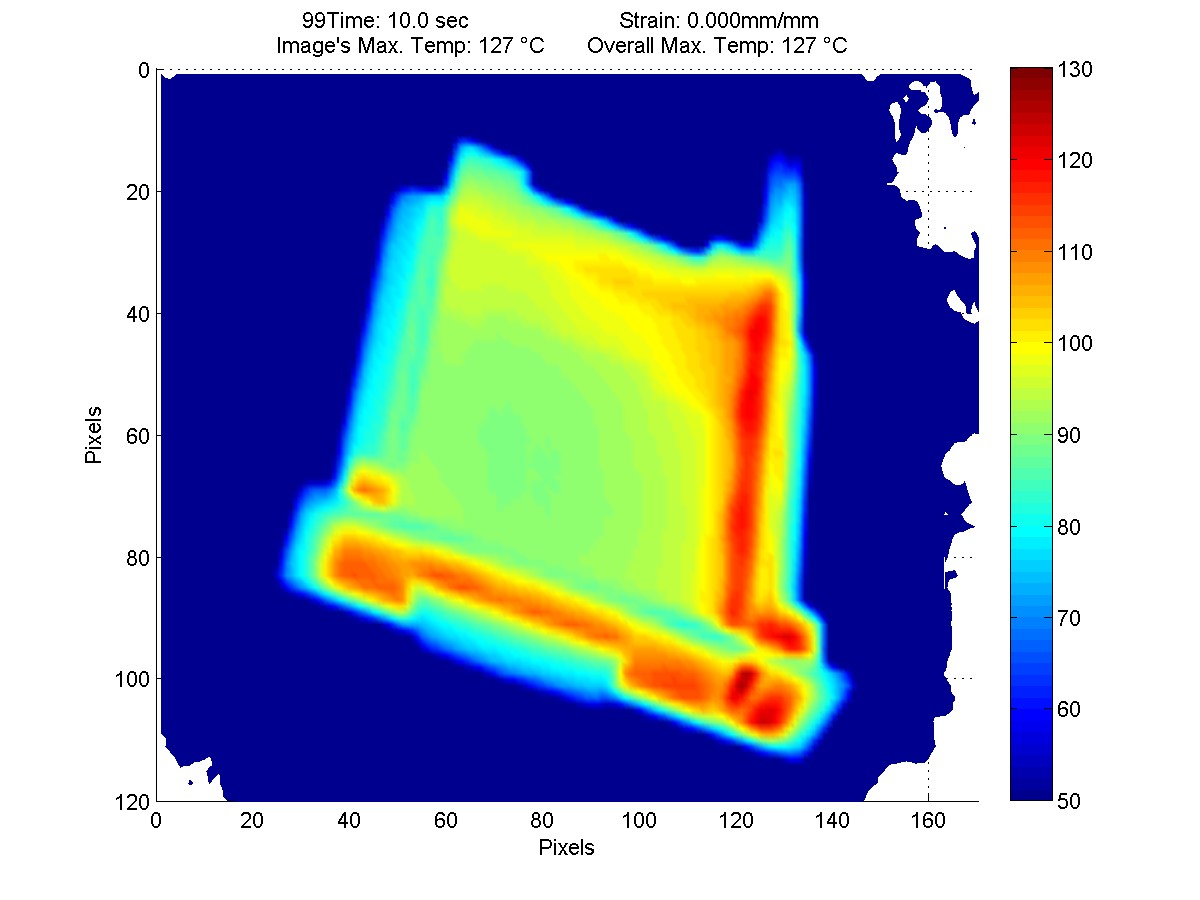

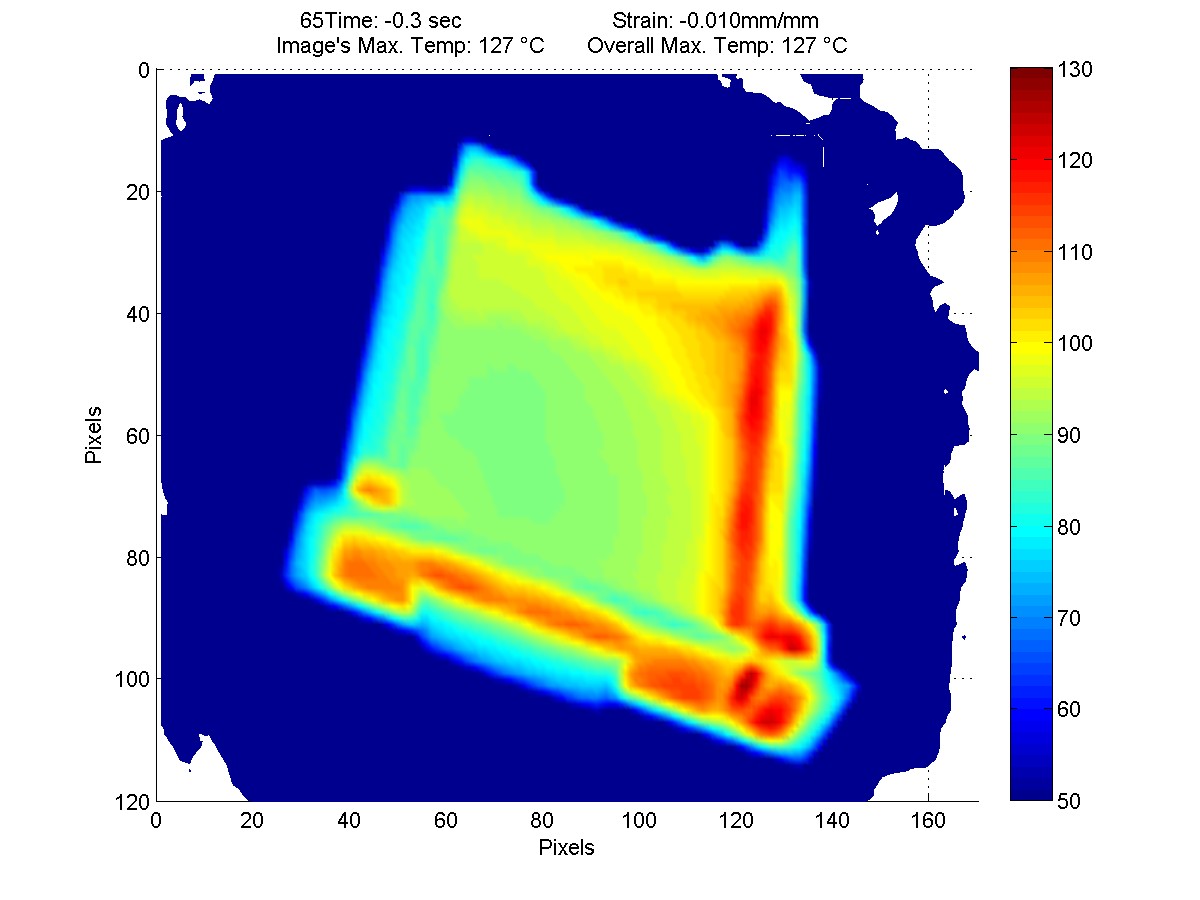

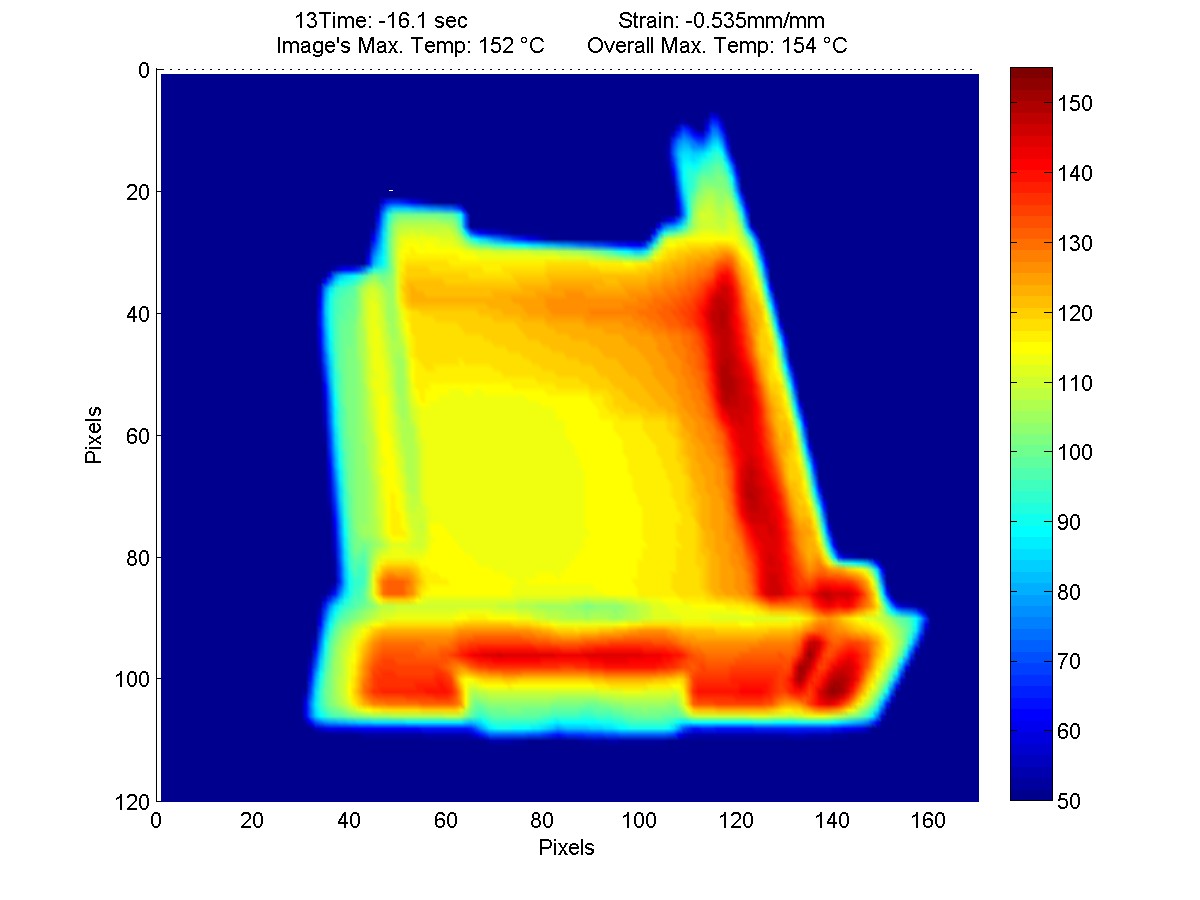

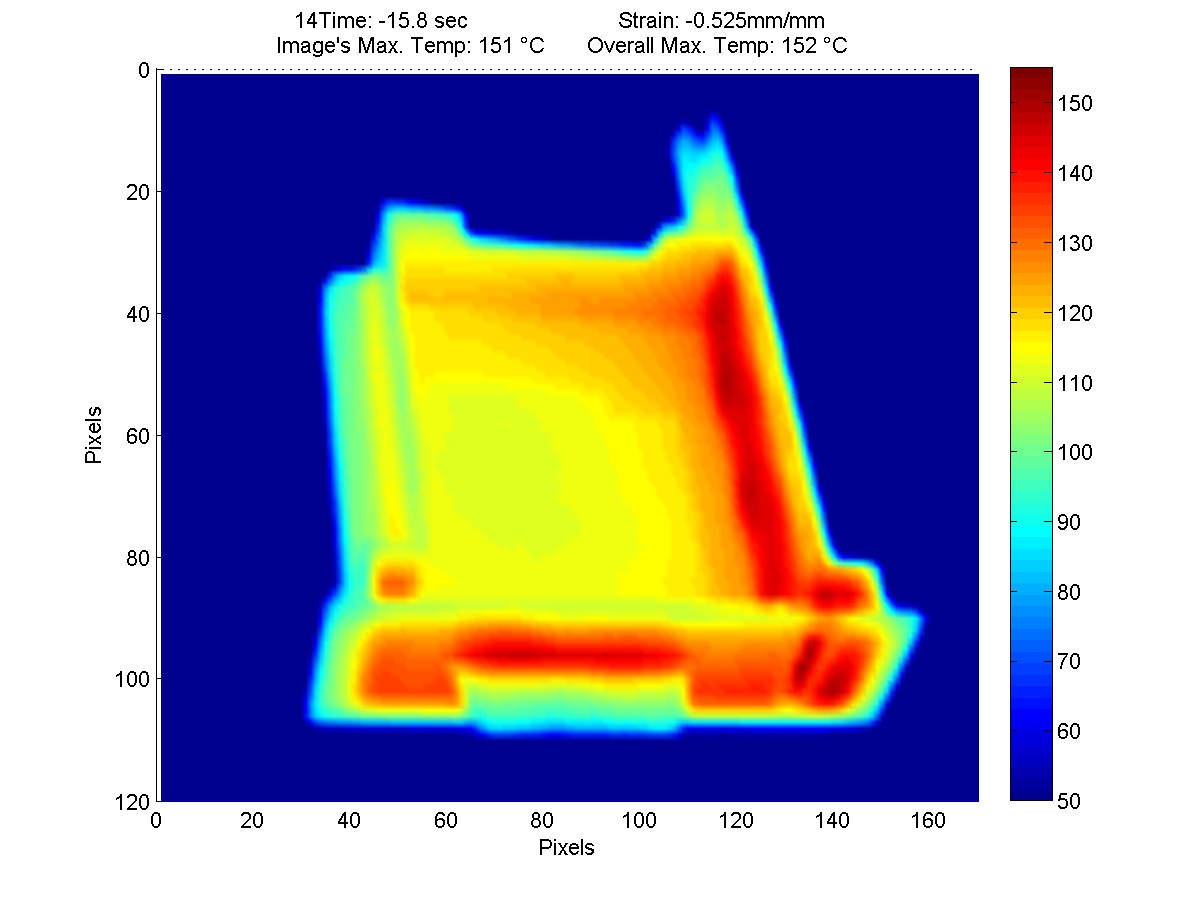

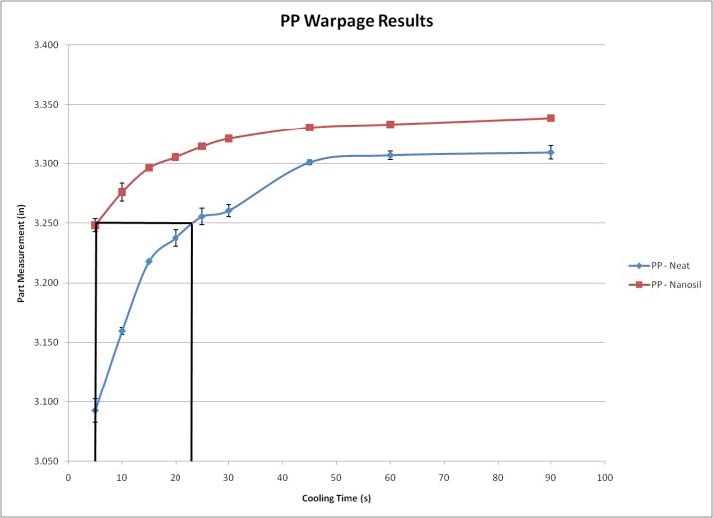

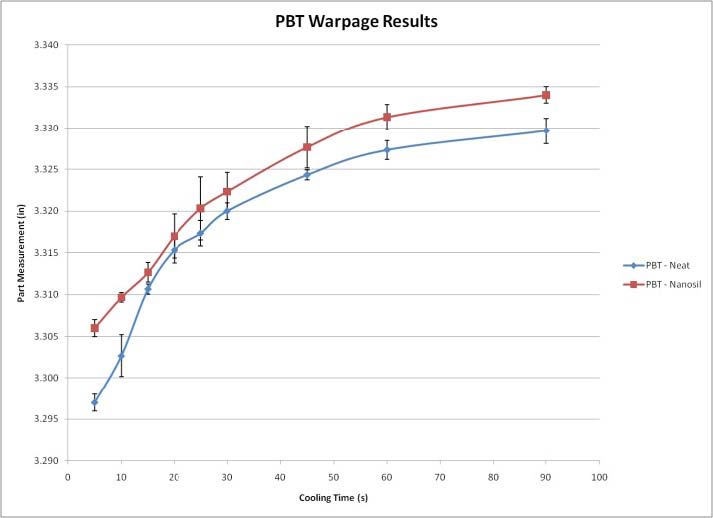

A cooling time study was performed to show the benefits of the Nan-O-Sil ASD additive. Through the use of an infrared camera, the part’s temperatures can be examined. The part’s warpage was also measured and compared to the neat resin for each material. The materials used in this study were PP, PBT - 33% glass filled, Nylon 6/6 – 33% glass-filled, ABS, and HDPE.

Through the use of the Nan-O-Sil silicon dioxide additive, cycle time can be reduced by as much as 70% in semi-crystalline materials.

Introduction

A common goal in Injection Molding is to reduce cycle time as it can save a company both time and money. Cooling time is typically the only phase of the injection molding cycle that has any amount of time that can be reduced. However, big reductions in cooling time could have an unwanted effect on a part’s dimension.

In this study, the temperature of the parts as well as warpage was measured to determine how well the Nan-O-Sil ASD additive could reduce the cooling time. A cooling time study was used to compare the neat resin to the resin with the Nan-O-Sil ASD. Several materials were run at the same cooling time to evaluate different combinations of materials.

An infrared camera was used to measure the part’s temperature at each run. In order to determine if cooling time could be reduced successfully, the part’s dimensions were recorded and averaged for each cooling time. A graph was created from this data to show the differences.

There were five materials used in this study. The semi-crystaline materials were Polypropylene (PP), Polybutylene Terephthalate (PBT), Nylon 6/6, and High Density Polyethylene (HDPE). The only amorphous material was Acrylonitrile Butadiene Styrene (ABS).

Statement of Theory and Definitions

A year ago we reported research data showing that very small amounts of ultra-fine silica, Nan-O-Sil ASD, can reduce injection molding cycle times by 20% to 30 % in PP, nylon, PBT, and ABS [i]. These results have since been confirmed in numerous commercial applications. The cycle time reductions have been demonstrated in 16 and 32 cavity molds along with other benefits such as reduced flow lines, improved color dispersion, and improved dimensional stability of PP, nylon and various glass-filled polyamides and other engineering plastics [ii].

Nan-O-Sil ASD is a high purity, amorphous, colloidal silica in the form of a white powder. The spherical particles range from 0.02 to 0.55 microns (20 to 550 nanometers). Energy Strategy Associates, Inc exclusively markets Nan-O-Sil ASD.

Description of Equipment and Process

The molding machine used in this study was a Husky Hylectric 90. The mold selected for this study was the Drawer mold. This mold was selected because the wall thickness varied in the part.

The PP material used was A. Schulman PP 3479-01. The PBT is 33% glass-filled resin, – Ticona Celenex 3309 HR. The nylon is Teknor 133GNT001, a 33% glass-filled resin. The ABS is SABIC (GE) Cyclolac GPM 5500-2502.

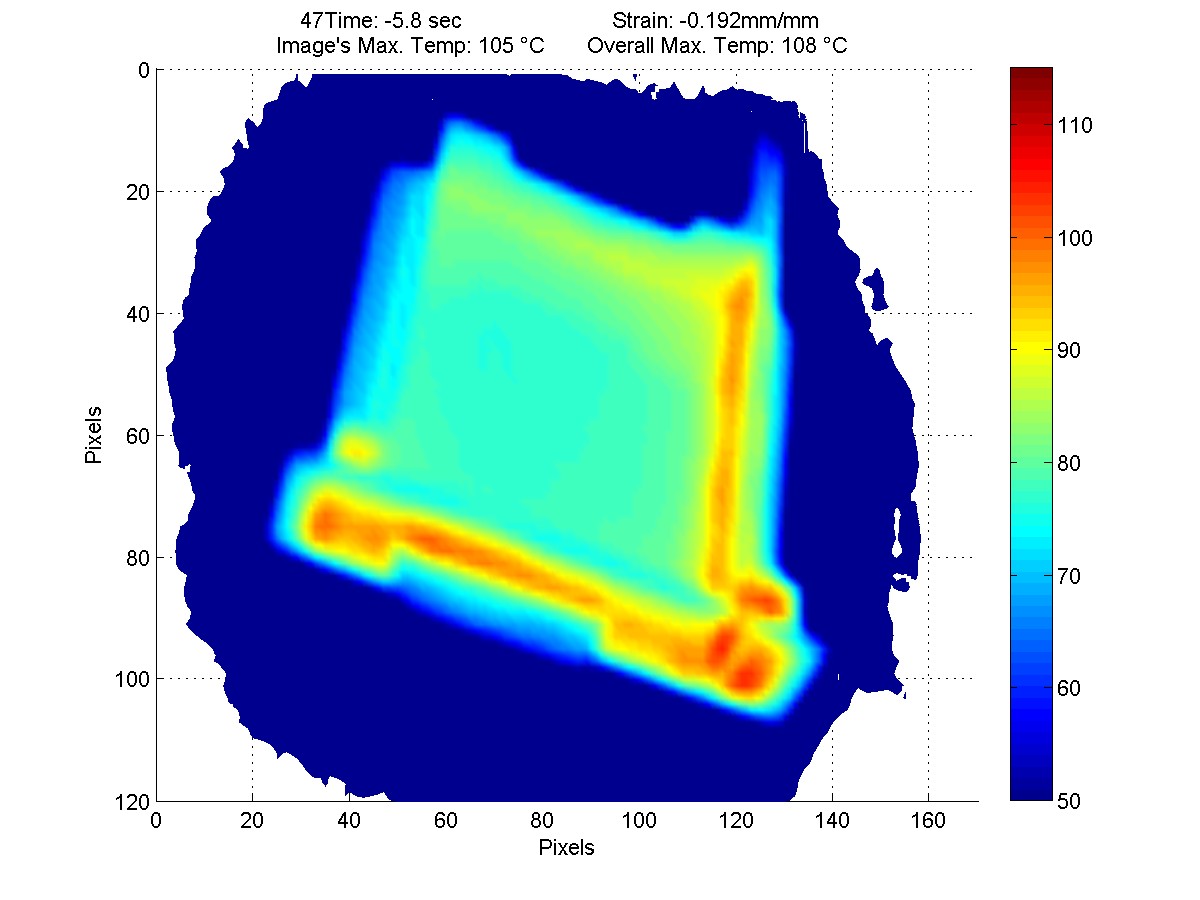

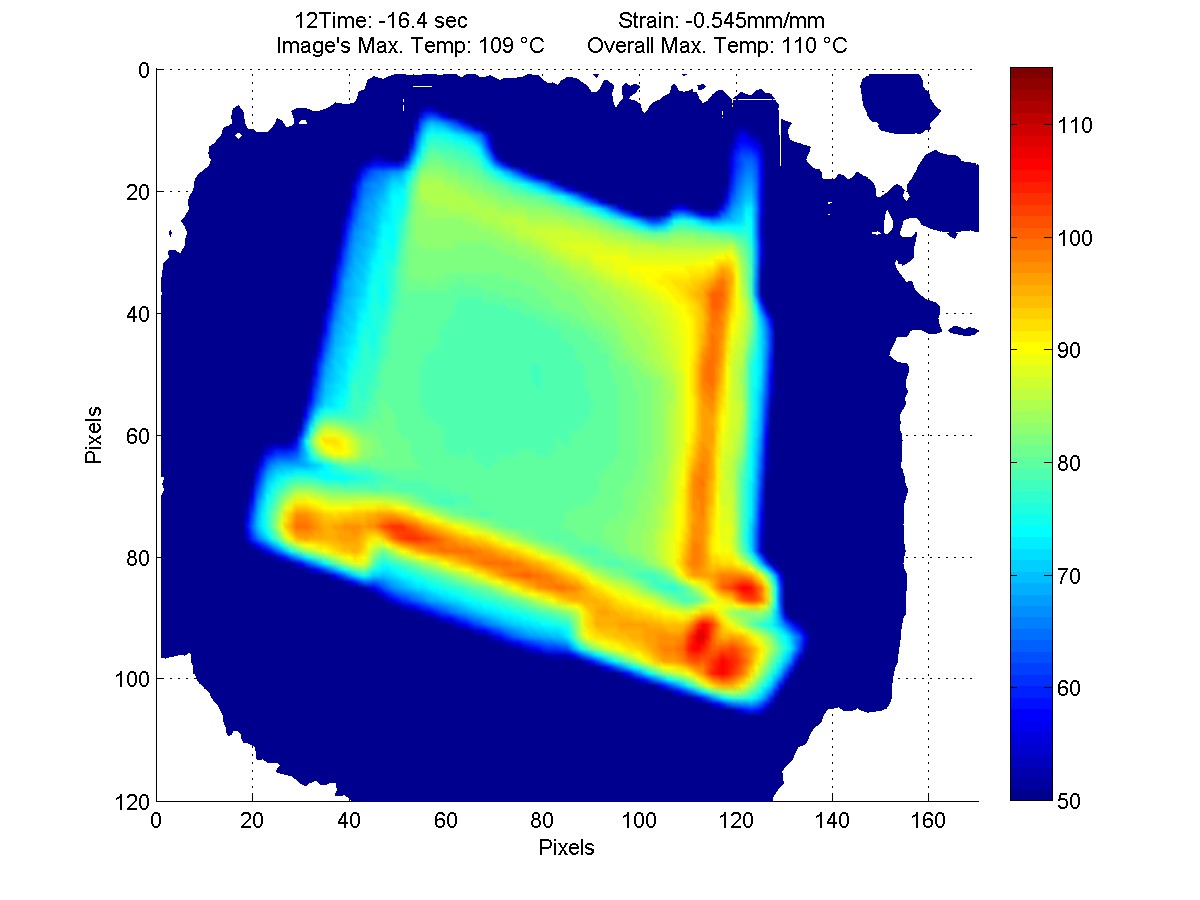

The part temperature was taken with the FLIR A-20 infrared camera. The data obtained from this camera was manipulated by MATLAB 2009a and software developed at Penn State Erie. A fixture was developed to ensure the parts orientation was consistent.

The parts warpage was measured with the OGP Avant 400 CFOV optical measuring device.

The nano-composite additive used in this study was Nan-O-Sil ASD, an ultra fine, high purity, amorphous colloidal silicon dioxide powder.

Application of Equipment and Process

The Nan-O-Sil ASD powder was hand mixed to 0.8% in the lab prior to running. For the hygroscopic materials, smaller batches were mixed during the process and brought to the molding machine when needed.

An optimum process was set for each material with 0.8% Nan-O-Sil ASD. The neat resins were run with the same process, although there was some adjustment for shot size.

The mold was run for 10 minutes to make sure it was in temperature equilibrium. The cooling time was set to 90s and six parts were molded. Data collection started on the seventh. Three parts were collected and infrared pictures were taken of each. The parts free fell from the mold and were collected by a gloved hand and placed into the fixture.

After the three samples were collected, the cooling time was dropped to 60s and three more samples were collected and measured in the same fashion. This was repeated for cooling times of 45s, 30s, 25s, 20s, 15s, 10s, and 5s. Between cooling time changes, six parts were run between the 90s, 60s, and the 45s cooling times. Four parts were run between the other cooling times.

The parts were stored in a climate controlled room to condition for a later measurement. The parts were then measured between two walls (1).

The data from the part measurements was placed into an Excel spreadsheet for each material. On each spreadsheet, the neat resin was compared to the Nan-O-Sil ASD.

Presentation of Data and Results

Interpretation of Data

Several molding trials had shown that the addition of Nan-O-Sil ASD shortened cycle time. These trials had shown the promise of cooling time reduction, but the mechanism for the reduction in cooling time was unknown.

The original hypothesis was that the Nan-O-Sil ASD additive would absorb the heat and cool the parts more quickly or help transfer the heat to the mold easily. The infrared pictures showed a different outcome.

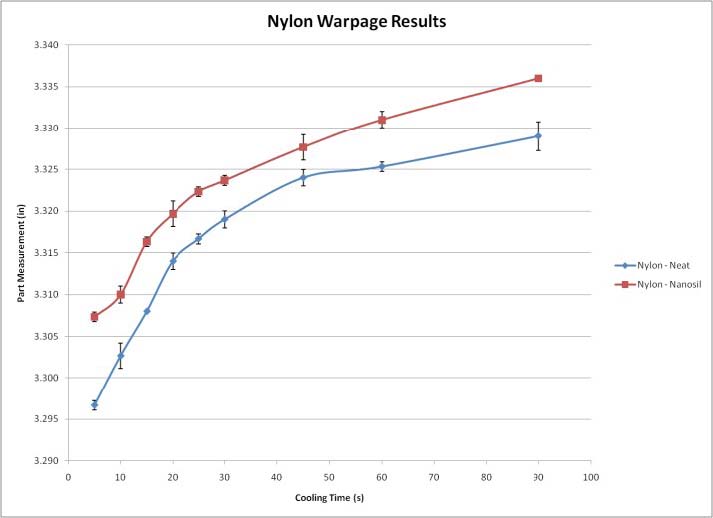

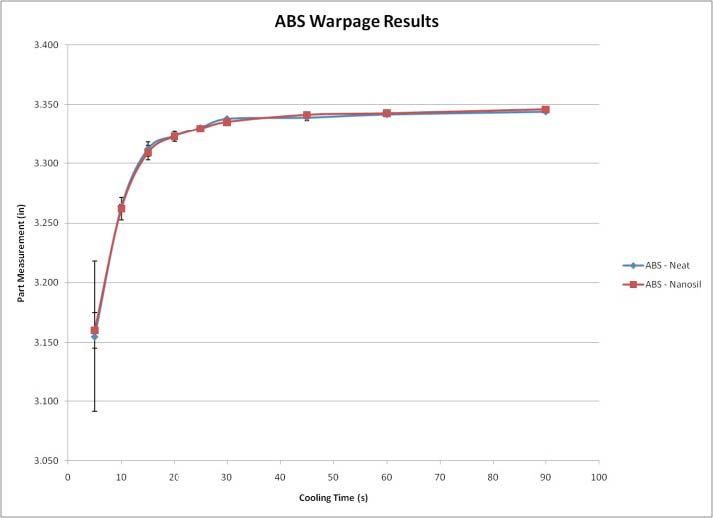

The temperatures of the Nan-O-Sil ASD parts are generally 1°C to 4°C higher than the neat resin parts. When looking at the bottom of the drawer, the Nan-O-Sil ASD also shows a higher temperature. It would be expected that the parts, at a higher temperature, would warp more than the cooler neat parts. The results showed that the addition of Nan-O-Sil ASD made the parts more dimensionally stable.

Preliminary DSC and SEM work show that there is less crystallinity in the PP parts. It is possible that the Nan-O-Sil ASD acts like a nucleating agent. It could create more individual crystals, but not as much total crystallinity as the neat resins. More tests need to be performed to confirm this hypothesis. This would explain why there is little effect on the ABS parts.

The addition of Nan-O-Sil ASD in the resin shows some significant reductions in cooling time. Several case studies have shown the same thing. PP shows the most reduction. It is the most crystalline of the polymers.

Future Work

More work needs to be done on the DSC and SEM to verify the preliminary results already run.

Since ABS was the only amorphous material run in the experiment, there is interest in seeing if Nan-O-Sil ASD affects other amorphous materials. Polycarbonate and PMMA may be tested with the Nan-O-Sil ASD.

Conclusions

Significant reductions in cooling time can increase a company’s profits. The addition of Nan-O-Sil ASD has shown a significant reduction in cooling time. In PP, it is 77%. In glass-filled PBT, it is 70%. Glass-filled Nylon has a 67% reduction. ABS shows no reduction in cooling time. The most likely cause of the reduction may be because the Nan-O-Sil ASD acts like a nucleating agent.

The Nan-O-Sil ASD may also inhibit polymer chain movement, just like a filler.

Acknowledgements

Many thanks go to my wife, Kim, and Shelley Readel for their constant revisions.

Key Words: Nan-O-Sil ASD, Infrared, IR, Injection Molding, Cycle Time Reduction

References

i. Sherman, Lilli, “Plastics Technology”, November 2008

ii. Naitove, Matthew H., “Plastics Technology”, December 2009

Close Up On Technology: Additives

Colloidal Silica Cuts Cycle Times In Molding Engineering PlasticsBy Matthew H. Naitove, Executive Editor

A year ago, we reported research showing that very small amounts of ultra-fine silica can reduce injection molding cycle times 20% to 30% in PP, nylons, PBT, and ABS (see Learn More). These results have since been confirmed in numerous commercial applications, according to Dr. Pravin L. Shah, head of Rheo-Plast Associates, a technical consulting firm that has been working on application development and laboratory testing of Nan-O-Sil ASD colloidal synthetic silica for its manufacturer, Energy Strategy Associates. According to Dr. Shah, the cycle-time reductions have been demonstrated in 16- and 32-cavity molds, along with other benefits such as reduced flow lines and improved dimensional stability. In addition, Nan-O-Sil ASD reportedly can improve color dispersion, allowing some molders to reduce colorant levels and thereby pay for the silica.

New laboratory test results from Rheo-Plast indicate that the benefits previously demonstrated also extend to other engineering resins such as acetal, glass-filled polycarbonate, PPS, and PEEK. Also new is the ability of Energy Strategy Associates to supply Nan-O-Sil ASD in compounded pellet concentrates with a wax or a desired resin as the carrier. Up to now, the colloidal silica has been supplied as a white powder with spherical particles of 0.02 to 0.55 microns (20 to 550 nanometers).

As shown in the accompanying table, addition of just 0.8% silica shortened injection molding cycle times for tensile test bars by 22% to 31% for unfilled acetal copolymer, PPS, and PEEK, as well as 33% glass-filled PC. Mechanical properties were generally maintained or improved. Although the data are not shown, Rheo-Plast also found that Nan-O-Sil ASD reduced cycle times by 5% with Noryl PS/PPO blend and 27% with HDPE. Dr. Shah also notes that the silica eliminated sticking problems that commonly occur with PPS.

It is believed that colloidal silica reduces cycle time by speeding cooling, even though the amount of additive is very small. The companies are working with the School of Polymer Processing and Materials Science at Penn State University in Erie, Pa., to study thermal effects inside the mold and arrive at a better understanding of how colloidal silica works to shorten molding cycles.

Dr. Shah says the cost savings possible from faster cycles outweigh the additive cost, which is less than 3˘ per pound of resin at the 0.8% addition level. That works out to less than $3/lb for the pure colloidal silica.

In addition to the new pellet concentrates, there are different ways to add Nan-O-Sil ASD in pure powder form at the processing machine. One is to tumble blend the additive with resin for 15 min before molding. According to Dr. Shah, there is no dusting because the silica tends to stick to the pellets. He adds that there is no safety hazard in handling Nan-O-Sil ASD powder.

Another method is to use a feeder at the machine throat to meter the silica in proportion to the resin. In addition, users of liquid colors or additives can mix the silica with the liquid prior to molding.

| Effect of Nan-O-Sil ASD on Properties of Engineering Plastics |

|||||||

| Material |

Cycle-Time Reduction, % | Tens. Str., kpsi | Elong. @ Yield, % | Flex. Mod., psi |

Notched Izod Impact, ft-lb.in. |

HDT @ 66 psi, F |

MFI, g/10 min |

| Acetal | |||||||

|

No Additive |

8500 | 6 | 360,000 | 1.2 | 310 | 9 | |

|

0.8% Nan-O-Sil |

23 | 9400 | 6.5 | 380,000 | 1.2 | 310 | 9 |

| PC + 33% Glass | |||||||

No Additive |

18,300 | 3.3 | 1,020,000 | 2 | 305 | 7 | |

0.8% Nan-O-Sil |

29 | 19,000 | 3 | 1,020,000 | 2 | 305 | 7 |

| PPS | |||||||

No Additive |

12,500 | 1 | 610,000 | 0.5 | 400 | 10 | |

0.8% Nan-O-Sil |

31 | 13,400 | 1 | 650,000 | 0.5 | 400 | 10 |

| PEEK | |||||||

No Additive |

14,500 | 5.1 | 600,000 | 1.6 | 320 | 17 | |

0.8% Nan-O-Sil |

22 | 15,500 | 6 | 700,000 | 1.6 | 320 | 17 |

Close-Up On Technology: Processing Aid

Colloidal Silica Processing Aid Slashes Molding Cycle TimesBy Lilli Manolis Sherman, Senior Editor

Ultra-fine synthetic silica particles have been shown in laboratory and commercial field trials to reduce injection molding cycle times by 20% to 30% in polypropylene, filled and unfilled nylon, PBT, and ABS. This processing advantage is accompanied by retention and even improvement of key physical properties. Other reported benefits are improved color dispersion and reduced flow lines and surface defects. What’s more, the silica additive is said to mix easily with resin pellets in a blender, so melt pre-compounding is not required.

Nan-O-Sil ASD additive is high-purity, amorphous, colloidal silica in the form of a white powder. The spherical particles range in size from 0.02 to 0.55 microns (20 to 550 nanometers). Nan-O-Sil ASD is manufactured and marketed by Energy Strategy Associates, Inc., which has been working with technical consulting and R&D firm Rheo-Plast Associates to develop applications for this additive. Headed by Dr. Pravin L. Shah, Rheo-Plast specializes in polymer rheology and its application to extrusion, injection molding, and compounding of engineering plastics and blends/alloys. Rheo-Plast conducted laboratory testing of Nan-O-Sil in a variety of resins. Dr. Shah supplied the test results to Plastics Technology for this article.

EXPERIMENTAL RESULTS

Injection molded sample bars were obtained by first tumbling resin pellets with Nan-O-Sil ASD for 15 min in a Conair blender. The additive coated the pellets well and uniformly, Shah reports.

The most dramatic results with Nan-O-Sil ASD are the cycle-time reductions for PP, unfilled nylon 6, glass-filled nylon 66, unfilled PBT, and ABS (see Table 1). The additive also shows utility as a reinforcing filler that can raise the stiffness of PP and both stiffness and strength of nylon 6 and PBT (Tables 2 to 5). Depending on the resin and the amount of Nan-O-Sil used, there was little or no sacrifice of other properties, such as elongation or toughness.

In glass-filled nylons, using larger amounts of Nan-O-Sil ASD appears to have potential for reducing the amount of glass fiber required to improve strength and stiffness. One trial compared the physical properties of 13% glass or 10% Nan-O-Sil in nylon 6. As shown in Table 4, colloidal silica imparted a greater increase in tensile strength and flexural modulus than did the glass fiber. According to Shah, an in-depth study of combinations of Nan-O-Sil ASD and glass fiber is under way and results will be published next year.

HOW IT WORKS

Although the precise mechanism by which Nan-O-Sil ASD reduces cycle times and improves strength properties of molded plastics is still unclear, Shah says the additive has been shown to work at low addition levels of 0.4% to 0.8% as a heat sink to reduce the amount of cooling required during molding. Based on Brabender torque rheometer data, he also postulates that the additive works as a processing aid to reduce the shear gradient at the gate and facilitate melt flow orientation.

Also not clearly understood at present is the apparent melting-point depression observed in PP, though no such effect was evident in nylon. Further work is under way to determine the additive’s behavior in melt processing.

| Table 2—Nan-O-Sil ASD in Polypropylene | ||||||||

|

Material |

Tensile Str. @ Yield, psi |

Elongation

@ Yield, |

Tensile Mod., psi | Gardner Impact, in.-lb/in. |

Flexural |

Flex. Str., psi | MFI, g/10 min | Melt Point, C |

| PP Control | 3000 | 9.7 | 145,000 | 2.18 | 112,000 | 3350 | 8 | 168 |

| PP/0.4% Nan-O-Sil | 3020 | 8.9 | 151,000 | 2.15 | 122,000 | 3570 | 8.2 | 163 |

| PP/0.8% Nan-O-Sil | 2930 | 8.2 | 144,000 | 2.12 | 118,000 | 3520 | 8.3 | 160 |

| TABLE 3—Nan-O-Sil ASD in Nylon 6 | |||||||

| Material | Tens. Str. @ Yield, psi | Elongation @ Yield, % | Tensile Mod., psi | Gardner Impact, in.-lb/in. |

Flexural Modulus, psi | Flexural Strength, psi | HDT @ 66 psi, F |

| Nylon 6 Control | 8710 | 4.5 | 315,000 | 2.18 | 224,000 | 9300 | 140 |

| Nylon 6 + 0.4% Nan-O-Sil |

8760 | 4.5 | 320,000 | 2.18 | 227,000 | 9330 | 140 |

| Nylon 6 + 0.8% Nan-O-Sil |

9020 | 4.6 | 320,000 | 2.15 | 237,000 | 9840 | 140 |

| TABLE 4—Nan-O-Sil ASD Vs. Glass Fiber in Nylon 6 | |||||||

| Material | Tensile Str. @ Yield, psi | Elongation @ Yield, % | Tensile Mod., psi | Gardner Impact, in.-lb/in. |

Flexural Modulus, psi | Flexural Strength, psi | HDT @ 66 psi, F |

| Nylon 6 Control | 8710 | 4.5 | 315,000 | 2.18 | 224,000 | 9300 | 140 |

| Nylon 6 + 13% Glass | 8760 | 4.5 | 320,000 | 2.18 | 227,000 | 9330 | 140 |

| Nylon 6 + 10% Nan-O-Sil |

9020 | 4.6 | 320,000 | 2.15 | 237,000 | 9840 | 140 |

| Table 5—Nan-O-Sil ASD in PBT | |||||||

| Material |

Tensile Str. @ Yield, psi | Elongation @ Yield, % | Tensile Modulus, psi | Gardner Impact, in.-lb/in. |

Flexural Modulus, psi | Flex. Str., psi | MFI, g/10 min |

| PBT Control | 7400 | 3.6 | 145,000 | 2.18 | 355,000 | 3350 | 8 |

| PBT+ 0.4% Nan-O-Sil | 7400 | 3.4 | 151,000 | 2.14 | 374,000 | 3570 | 8.2 |

| PBT+ 0.8% Nan-O-Sil | 7600 | 3.2 | 144,000 | 2.1 | 380,000 | 3520 | 8.1 |

A Study on the Effect of Nan-O-Sil ASD on Cooling Time Reduction

A Study of The Effect of Nan-O-Sil ASD Processing Aid For Significantly Reducing The Cycle Time in Injection Molding And Improving Strength and Toughness of PP, nylons, and PBT

Dr. Pravin L. Shah

Rheo-Plast Associates, Inc.

Reading PA 19608

ABSTRACT

A comprehensive technical investigation was undertaken to determine the effect of Nan-O-Sil ASD, an ultra fine, high purity, amorphous colloidal Silicone Dioxide powder (see Table 1 for chemical description of the additive) on injection molding cycle time and physical properties of PP, unfilled and glass filled nylon 6, glass filled nylon 66, and unfilled PBT.

The results of this study show that at 0.4 to 0.8 weight percent concentration the Nan-O-Sil ASD additive is found to be very effective in significantly reducing the cycle time in injection molding and improving the strength and toughness of PP, nylon 6 and nylon 66, and PBT materials as described below:

- The Nan-O-Sil ASD additive was found to be a very effective processing aid to reduce the injection molding cycle time by 20 to 30 % in unfilled nylon 6, glass filled nylon 66, and unfilled PBT, ABS and PP (see Table 2).

- The Nan-O-Sil ASD additive was found to improve the tensile strength and flexural modulus of nylons, PBT, and PP resins from 3 to 8 % ( see Tables 3 to 6).

- The Nan-O-Sil ASD additive was found to improve the color dispersion in injection molded parts of filled and unfilled polymers while reducing the flow lines and surface defects.

- Brabender torque rheology data shows a reduction in loading torque and equilibrium viscosity of PP with 1 % Nan-O-Sil ASD additive indicating its potential use as an effective processing aid to reduce the energy and motor torque in polymer processing.

- Further work is planned to investigate the usefulness of the Nan-O-Sil ASD additive as a heat sink and processing aid for both extrusion and injection molding of PE, PVC, PP, and nylons to reduce the cost and improve the productivity.

- Further work is also planned to understand the mechanism of the Nan-O-Sil ASD additive as a reinforcement filler to potentially use it as a synergistic filler with glass fiber for faster cycle time and to reduce the mold wear in injection molding and extrusion.

Description of the Nan-O-Sil ASD material

Nan-O-Sil ASD is an ultra fine (sub micron), spherical discrete, non-fused, high purity Amorphous Colloidal Silica Powder produced through high temperature hydrolysis in a hydrogen oxygen flame. Due to its unique ability to work as a heat sink and processing aid, it is designed to offer specific benefits in polymer processing as described in this paper. Table 1 describes its chemical and physical properties in detail. The Nan-O-Sil ASD additive is exclusively marketed by Energy Strategy Associates, Inc. located in Old Chattam, NY. Outline of the Experimental Work

Outline of the Experimental Work

We have included four very important polymers in this study to determine the effect of adding the Nan-O-Sil ASD additive at 0.4% and 0.8% with each polymer to measure its effect on injection molding cycle time and physical properties. The injection molding grade resins considered for this study are:

- Schulman polypropylene - Polyflam 1058 with melt flow index range of 8 to 10

- Unfilled nylon 6 - Chemlon 212 - melt flow index range 8 to 10

- Glass filled nylon 6 - Chemlon 214 G - melt flow index 7 to 9

- BASF Ultradur unfilled PBT - melt flow index 8 to 10

The Nan-O-Sil ASD additive was tumble mixed for fifteen minutes in a Conair blender with each resin. The additive was found to coat the resin pellets very well and no problem was found in obtaining a uniform mix of the additive with each polymer. As shown later in the report, the dispersion of the additive was very good with each polymer based on the consistency of the physical properties of the molded specimen. As a result, we did not do any melt compounding of the additive in this study since the additive is very easy to mix with the polymer in a blender.

The three blends of each polymer were prepared and identified as control (no additive), 0.4% additive mix, and 0.8% additive mix. The blends were then injection molded on a 110 ton Cincinnati molding machine using a ASTM mold to make the tensile bars.The molded tensile bars were used to measure the physical properties of each polymer blend with the Nan-O-Sil ASD additive as discussed below.

Three repeat molding trials were made with each polymer to test the effect of 0.8% additive on cycle time and the results are shown below.

Results and Discussion - Effect of Nan-O-Sil ASD on Injection Molding Cycle Time and The Physical Properties of each Polymer

Table 1 describes the chemical and physical attributes of the Nan-O-Sil ASD additive. It is a very free lowing powder that has unique ability to coat the resin pellet during the mixing cycle. Minimum dusting was noticed while introducing the blends in the hopper for the molding study. Each polymer was blended with the Nan-O-Sil ASD additive at 0, 0.4, and 0.8 weight % additive for fifteen minutes in a Conair blender. Due to the ease of the mixing of the additive, we did not do any melt blending of the additive which can be done easily for a large volume operation.

The molding trials of each blend were conducted on a 110 ton Cincinnati molding machine using an ASTM mold to produce tensile bars which were then used to measure the physical properties.

Based on our molding experience of more than twenty years, we set the melt temperature for PP and nylon 6 at 400 F while the PBT blends were molded at 500 F melt temperature. Typical cycle time to mold the ASTM test bars was determined to be approximately 30 seconds for each resin considered in this study.

Generous amounts of test bars were produced from each resin using 0%, 0.4% and 0.8% Nan-O-Sil ASD additive. After producing the required samples for measuring the physical properties of each blend at steady state conditions using cycle time of 30 seconds as a bench mark, we then devoted considerable time to measure the effect of 0.8% Nan-O-Sil ASD additive on the cycle time for each material as described below.

EFFECT OF NAN-O-SIL ASD ON CYCLE TIME

Table 2 shows the results of cycle time with three repeat mold trials of each resin with 0.8% Nan-O-Sil additive. Our objective was to determine if the additive can allow one to reduce the cycle time without affecting the mold quality in terms of flow lines, splash, or warpage. As shown in Table 2, we are able to reduce the cycle time by 22 % for PP resin with the additive. The molded test bars were all checked for tolerances and surface quality. Each of the bars was found to be within the specification of the mold tolerances at reduced cycle time of 22%.

We believe the Nan-O-Sil ASD additive may be working as a heat sink to reduce the amount of cooling required during the molding. We further postulate that the additive may be working as a processing aid for each polymer to reduce the shear gradients at the gate and facilitates the melt flow orientation based on the Brabender torque rheometer data shown in Figure 1. Note that 1% additive significantly lowers the loading torque and the equilibrium torque of PP resin as shown in Figure 1 indicating lower motor amps and reduced energy requirements during molding. We believe further work on this additive to determine its melt flow behavior will be very useful to broaden its applications in extrusion and injection molding to reduce the energy, shear gradients, and melt temperature due to reduced frictional heat based on our thesis that Nan-O-Sil ASD may be working as an effective heat sink in polymer processing.

Nylon 6 and nylon 66 are very important molding materials with large volume usage in a variety of molding applications. In this study we evaluated the effect of Nan-O-Sil ASD additive on cycle time for unfilled nylon 6 and 33 % glass filled nylon 66. As shown in Table 2, the additive reduces the cycle time of unfilled nylon 6 by 24 %. The results of Nan-O-Sil ASD are even more dramatic as reported in Table 2 to attain 32 % reduction in cycle time with 33 % glass filled nylon 66.

The effect of Nan-O-Sil ASD on PBT and ABS resins is equally impressive to reduce the cycle time by 25% as shown in Table 2. As we know, these two polymers along with nylons and PP are major work horses in the injection molding market and a dramatic reduction of cycle time (20 to 30%) from a small (< 1%) usage of the Nan-O-Sil ASD additive can be very powerful cost reduction incentive for every molder to be more competitive in the Global economy.

EFFECT OF NAN-O-SIL ASD ON THE PHYSICAL PROPETIES OF PP, NYLON 6, AND PBT

Effect of 0.4 and 0.8 wt % Nan-O-Sil ASD additive on the physical properties were measured in great detail by using the carefully molded tensile bars from each of the three blends containing 0, 0.4, and 0.8% additive.

Table 3 shows the ASTM physical properties of PP with Nan-O-Sil ASD including tensile stress and elongation at yield, tensile stress and elongation at break, Gardner impact, and flex modulus and flex strength. As shown in the data in Table 3, tensile properties at yield are not affected much by the additive. However we see an improvement in flex modulus indicating higher toughness attributed by the additive with PP.

Table 4 shows similar results of the physical properties of unfilled nylon 6 with Nan-O-Sil ASD additive. The tensile properties at yield show some increase and the flex modulus and flex strength also show 3 to 8 % increase in values due to the addition of Nan-O-Sil ASD additive to nylon resin. It could be concluded that the Nan-O-Sil ASD additive may be working as an effective filler to improve the strength and toughness of these materials. The exact mechanism is not understood at this time but additional work is planned to explain the reinforcement attributes of the additive and will be reported in future work.

Table 5 shows a comparison of the physical properties of 13 % glass filled nylon 6 with a 10 % Nan-O-Sil ASD additive in nylon 6. As we know glass fiber increases the tensile strength and flex modulus very significantly as shown by the data of unfilled nylon vs. 13% glass filled nylon. We wanted to see how effective the Nan-O-Sil ASD additive is as a filler in comparison to glass fiber with nylon. The last five rows of Table 5 show the effect of 10% Nan-O-Sil ASD in nylon 6. Note that the additive is found to increase the tensile strength and flex modulus of nylon 6 significantly without any glass fiber included in this matrix. Theses results indicate that the Nan-O-Sil ASD additive could be used in a synergistic way to use it with glass fiber to attain similar strength properties while reducing the mold wear and improving the cycle time by reducing the amount of glass fiber. An in depth study of the Nan-O-Sil ASD /glass fiber synergy is planned for future work with different polymers and the results will be reported in the near future.

Table 6 shows the effect of Nan-O-Sil ASD on the physical properties of unfilled PBT which is used in molding of electrical components very exclusively. While most of the properties remain unaffected, the strength and toughness increases as shown in the tensile strength and modulus data.What is very interesting to note is that while the Nan-O-Sil ASD does not show any negative effect on the physical properties and it does show 3 to 8 % increase in strength and toughness of PP, nylon, and PBT, the additive could be considered as a good reinforcement filler for these polymers reported in this study to improve tooling wear, and reduce the energy cost. The real benefit of the Nan-O-Sil ASD additive is found to be the significant reduction (20 to 30 %) in cycle time as discussed above.

EFFECT OF NAN-O-SIL ASD ON COLOR DIPERSION AND FLOW LINES

We carefully examined the effect of Nan-O-Sil ASD in molding of PP and nylons for color dispersion ability and overall surface quality. We are pleased to report that the additive was found to be very effective in improving the color dispersion for red, yellow, and gold colorants in PP and nylons. The Nan-O-Sil ASD additive is also found to improve the flow lines and surface imperfections in glass filled nylon 6 and nylon 66.

CONCLUSIONS AND RECOMMENDATIONS

Based on the results of this study, we can draw the following meaningful conclusions about the effectiveness of the Nan-O-Sil ASD additive:

- The Nan-O-Sil ASD additive was found to be very effective processing aid to reduce the injection molding cycle time by 20 to 30 % in unfilled PP, nylon 6, glass filled nylon 66, PBT and ABS materials.

- The Nan-O-Sil ASD additive was found to be an effective reinforcement filler to improve the tensile strength and flexural modulus of nylons, PP, and PBT by 3 to 8 %.

- The Nan-O-Sil ASD additive was also found to improve the color dispersion of the molded parts of filled and unfilled PP and nylons while reducing the flow lines and surface defects.

- Nan-O-Sil ASD additive has the potential to work in synergy with glass fiber to provide good strength properties with less wear of the tooling and reduced energy in molding of plastic parts.

- Brabender torque rheology data of 1 % Nan-O-Sil ASD additive with PP shows a significant reduction on the loading torque and lowering of the equilibrium torque. Theses results indicate the additive may be working as a heat sink to reduce the motor torque and energy input in molding and extrusion process by reducing the frictional heat. Additional work is required in this area to explain the melt flow behavior of the Nan-O-Sil ASD additive with different polymers.

At this point we are not able to explain the precise mechanism how the additive is working to reduce the cycle time and improve the strength properties with the polymers reported in this study. However, we postulate that additional work will provide better understanding of our theory that the Nan-O-Sil ASD is a very useful additive for injection molding applications based on its ability to work as a heat sink and presumably work as a coupling agent and a filler in synergy with glass fiber and other fillers to offer a less abrasive filler option to reduce the tooling wear with reduced energy and lower cost material formulation matrix with better melt flow orientation for both unfilled and filled polymers. New developments on the Nan-O-Sil ASD blends technology will be reported in the next technical paper.

Nan-O-Sil ASD Molder's Guide

Processing Cycle Time

Nan-O-Sil ASD is an ultra fine (sub micron), bright, white, non-porous, high purity amorphous colloidal silica dioxide powder exclusively marketed by Energy Strategy Associates, Inc. It is FDA approved for usage of less than 1 % and it does not need drying.

Plastics Technology has reported a very useful technical paper on Nan-O-Sil ASD in the November 2008 issue showing dramatic improvements (20-30%) in injection molding cycle time of many resins including PP, nylons, ABS, and PBT.

Nan-O-Sil ASD works very effectively at 0.4% to 0.8% level for most molding applications to reduce the cycle time and improve the flow lines, color dispersion and certain physical properties. This additive is very easy to tumble mix with the base resin at desired level and it tends to cling to the resin pellet well enough that one does not have to melt compound it. Tumble mixing of Nan-O-Sil ASD for fifteen minutes will provide an excellent dispersion for molding applications.

If a molder is feeding the resin directly from a silo and needs to meter the Nan-O-Sil ASD additive in the feed throat of the molding machine, one can use a volumetric feeder or a gravimetric feeder offered by one of the following companies. These feeders are a proven technology to meter accurate amounts of an additive like a colorant or a processing aid and the screw in the molding machine will provide good mixing to attain homogenous mix of the Nan-O-Sil ASD with the resin feedstock.

You can contact any of the following companies to acquire a feeder to introduce the additive directly in the feed throat, which eliminates the need to do tumble mixing. For further technical assistance on Nan-O-Sil ASD usage for molding applications, please contact Dr. Pravin Shah of Rheo-Plast Associates Inc. at 610-780-2855 or email him at : pshah@1usa.com

K-Tron Process Group

P.O. Box 888

Pitman, NJ 08071

Phone 856-589-0500

Conair Group

200 West Kensinger Drive

Cranberry TWP, PA 16066

Phone 724-584-5000

Website : conairgroup.com

Sterling Corp.

2900 S. 160th street

New Berlin, WI 53151

Phone 262-641-8610

Nan-O-Sil ASD Extrusion Characteristics Based on Brabender Torque: Rheometer Study

| Material Formulation | Leading Torque or Energy Requirement | Eq Torque/Melt Viscosity | Effect on the Melt Temp (F) | Pressure Flow Variation |

| PP - Control | 1000 | 330 | 207 | 5% |

| PP + 1% N | 900 | 360 | 205 | 4% |

| PP + 3% N | 800 | 390 | 204 | 1.50% |

| PE Control | 1200 | 450 | 206 | 6% |

| PE + 1% N | 1000 | 480 | 205 | 3% |

| PE + 5% N | 850 | 510 | 205 | 2% |

| PVC - Control | 1400 | 800 | 210 | 7% |

| PVC + 1%N | 1200 | 810 | 209 | 5% |

| PVC + 2%N | 1000 | 830 | 206 | 3% |

| Nylon 66 - Control | 800 | 480 | 280 | 6% |

| Nylon 66 + 1% N | 700 | 490 | 277 | 4% |

| Nylon 66 + 3% N | 625 | 510 | 276 | 10.50% |

| Overall Comments on Nan-O-Sil Effectiveness for Extrusion Applications: | ||||

| Very Effective to reduce energy Req. in Extrusion |

Slightly Raises melt viscosity as a filter |

Does Not reduce melt temp significantly |

Very Effective in reducing melt flow variation |

|